One of the main advantages of organic polymer monoliths is their simple preparation and surface modification. Thus, my research focuses on tailored preparation of organic polymer monoliths and characterization of their properties. In order to improve them and prepare better and better separation devices.

I understand my research as a time line. You always follow some imaginary direction and try to move your knowledge from one point to another. The next lines follow my list of publications and describe individual steps of my research from its beginning up until now. So it is never ending story with open and unknown end. If you would like to know more, feel free to check my list of publications or contact me directly.

Characterization of polymethacrylate monoliths

At the beginning we have compared inorganic silica-based monoliths with monolithic stationary phases prepared from methacrylate monomers. By changing the polymerization mixture composition, and 1,4-butanediol or 1-propanol as porogenic solvents in particular, columns with different morphology, efficiency and selectivity can be prepared. Higher concentrations of propanol in the polymerization mixture enhanced the lipophilic character of the polymethacrylate monolithic stationary phases.

At the beginning we have compared inorganic silica-based monoliths with monolithic stationary phases prepared from methacrylate monomers. By changing the polymerization mixture composition, and 1,4-butanediol or 1-propanol as porogenic solvents in particular, columns with different morphology, efficiency and selectivity can be prepared. Higher concentrations of propanol in the polymerization mixture enhanced the lipophilic character of the polymethacrylate monolithic stationary phases.

Porous properties of stationary phases

My favorite topic. We have studied effects of polymerization mixture composition on porous properties of polymer monoliths. Excesive number of columns have been prepared and mathematical models describing formation of both large flow-through pores and small mesopores were developed. According to these models higher concentration of 1,4-butanediol in the polymerization mixture enhances formation of large pores, while higher amount of 1-propanol supports formation of small pores.

We have also tested possibility of application of monolithic stationary phase with high concentration of small pores in size-exclusion chromatography.

We have also tested possibility of application of monolithic stationary phase with high concentration of small pores in size-exclusion chromatography.

In addition to these models we have compared mercury intrusion porosimetry and inverse size-exclusion chromatography porosimetry techniques. While mercury intrusion covers large range of pore sizes (nm – μm) its disadvantage is that the material is measure at dry state while inverse size-exclusion determines pore size distribution (of small nanometer sized pores) in swollen state and is therefore more suitable for determination of porous properties of monolithic stationary phases.

We have also compared accessibility of the pores in various types of commercially available columns for large molecules (such as proteins) and its effect on the validity of general model describing gradient elution. While the accessibility of the pores should be considered when using fully porous particles, in case of non-porous, superficially porous or monolithic stationary phases its effect is limited.

Enzymatic reactor

I always wanted to build one. Really. I have prepared a monolithic lipase reactor for biodiesel production by transesterification of triacylglycerides into fatty acid methyl esters. To my best knowledge it is demonstrated for the first time that organic polymer-based enzymatic reactor can work also in fully organic environment.

I always wanted to build one. Really. I have prepared a monolithic lipase reactor for biodiesel production by transesterification of triacylglycerides into fatty acid methyl esters. To my best knowledge it is demonstrated for the first time that organic polymer-based enzymatic reactor can work also in fully organic environment.

After the optimization of immobilization and working conditions I was able to show transesterification of triacylglycerides into fatty acid methyl esters in common kitchen oil sample. The reactor has showed very high robustness and stability with decrease in its activitiy after flushing of 1000 substrate volumes through the reactor.

Small molecules separation

Hydrophilic interaction chromatography (HILIC) is one of the hottest topics in current chromatography. It allows separation of highly polar compounds which are usually very difficult to separate in reversed-phase chromatography. We have prepared polymethacrylate monolithic based on zwitterion methacrylate monomer and tested them for the separation of polar compounds including phenolic acids or flavones.

Hydrophilic interaction chromatography (HILIC) is one of the hottest topics in current chromatography. It allows separation of highly polar compounds which are usually very difficult to separate in reversed-phase chromatography. We have prepared polymethacrylate monolithic based on zwitterion methacrylate monomer and tested them for the separation of polar compounds including phenolic acids or flavones.

We have tested several polar solvents as pore forming solvents and ended up with tertiary porogenic mixture with 1,4-butanediol, 1-propanol and water. This mixture allows both simple introduction of polar hydrophilic monomer in the polymerization mixture and fine tuning of the porous properties of resulting monolith. The prepared monoliths do not dazzle with the highest efficiency but their selectivity is comparable to commercially available ZIC-HILIC column.

It was our first step in our attempts to prepare efficient column suitable for the fast separation of small molecules.

Hypercrosslinked monoliths

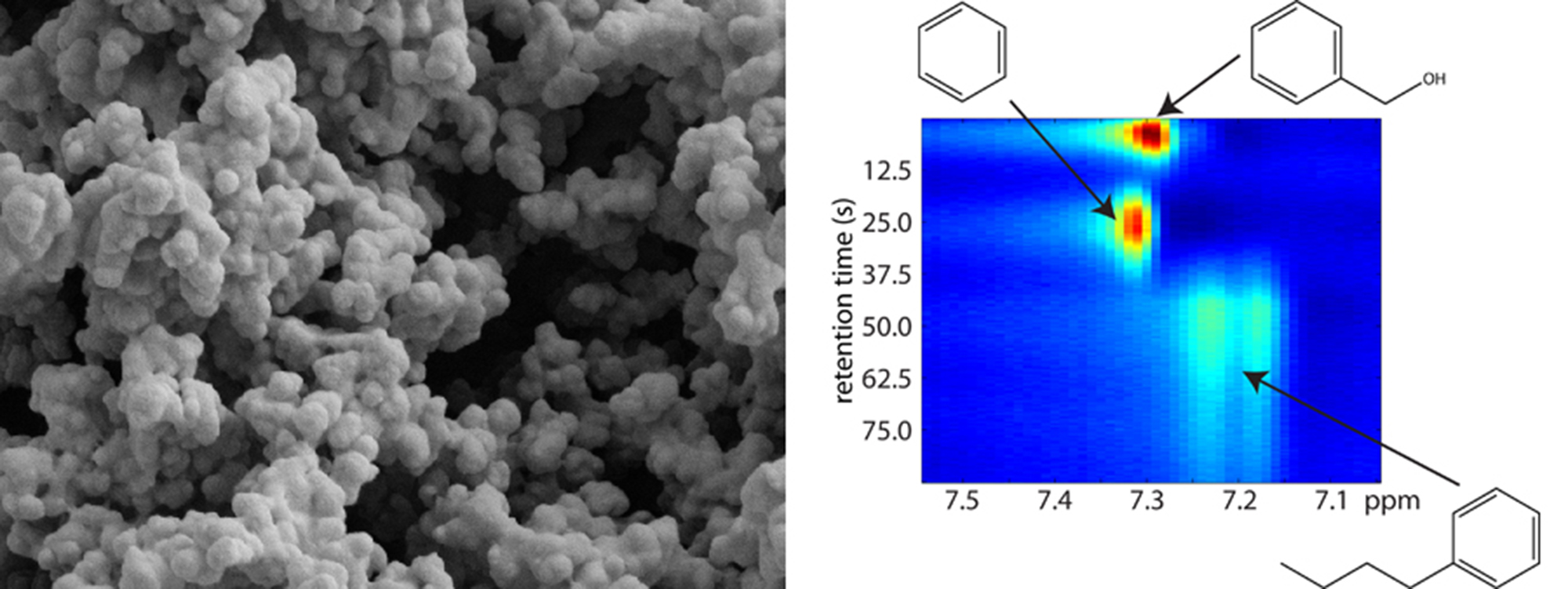

And styrenic hypercrosslinked monoliths are such columns. These materials are suitable for fast separation of small molecules. We were able to separate small alkylbenzenes in less then 2 minutes in isocratic mobile phase. Additionally, we have used these columns in very drastic conditions (high flow-rates and sample overloading) and used them successfully for online hyphenation with NMR detection.

Moreover, with NMR detection we were able to characterize flow profile of the mobile phase flowing through the monolithic column. Opposite to the parabolic flow profile in empty capillary the flow in monolithic material is very flat which might reffer to their high efficiency.

Last but not least we achieved size-exclusion separation of polystyrene standards on hypercrosslinked monolith.

Currently, were are working on the surface modification of hypercrosslinked monolithic stationanry phases.

Currently and in the future is monolith understand as porous rod inside the capillary, which arise during the in-situ polymerization. There are silica-based and organic polymer based monoliths, which are very easy to prepare and used like a stationary phase for HPLC and CEC.

Currently and in the future is monolith understand as porous rod inside the capillary, which arise during the in-situ polymerization. There are silica-based and organic polymer based monoliths, which are very easy to prepare and used like a stationary phase for HPLC and CEC.

We have also tested possibility of application of monolithic stationary phase with high concentration of small pores in size-exclusion chromatography.

We have also tested possibility of application of monolithic stationary phase with high concentration of small pores in size-exclusion chromatography. I always wanted to build one. Really. I have prepared a monolithic lipase reactor for biodiesel production by transesterification of triacylglycerides into fatty acid methyl esters. To my best knowledge it is demonstrated for the first time that organic polymer-based enzymatic reactor can work also in fully organic environment.

I always wanted to build one. Really. I have prepared a monolithic lipase reactor for biodiesel production by transesterification of triacylglycerides into fatty acid methyl esters. To my best knowledge it is demonstrated for the first time that organic polymer-based enzymatic reactor can work also in fully organic environment. Hydrophilic interaction chromatography (HILIC) is one of the hottest topics in current chromatography. It allows separation of highly polar compounds which are usually very difficult to separate in reversed-phase chromatography. We have prepared polymethacrylate monolithic based on zwitterion methacrylate monomer and tested them for the separation of polar compounds including phenolic acids or flavones.

Hydrophilic interaction chromatography (HILIC) is one of the hottest topics in current chromatography. It allows separation of highly polar compounds which are usually very difficult to separate in reversed-phase chromatography. We have prepared polymethacrylate monolithic based on zwitterion methacrylate monomer and tested them for the separation of polar compounds including phenolic acids or flavones.