From my point of view, the preparation of polymer monolithic stationary phases suitable for the separation of small molecules is one of the hotter topics now in monolithic chromatography. There are several ways how to improve their separation power for small molecules. It is possible to increase their surface area either by hypercrosslinking modification or with the combination of non-polar and polar monomers. Another possibility is to prepare low-surface area (but efficient) materials by the termination of the polymerization reaction at the early stages or by application of crosslinking monomer with longer atom chain in between two methacrylate units.

We have extended the later approach and recently published the article describing the one-step preparation of highly efficient columns for the separation of small molecules.

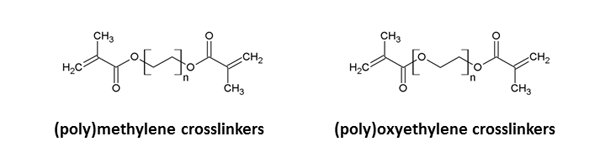

By selection of a suitable dimethacrylate cross-linking monomer, the polymerization conditions can be tuned to prepare capillary polymethacrylate monolithic columns suitable for separations of either low-molecular compounds (alkylbenzenes) or of high-molecular biopolymers. In the presented paper we described the preparation of 8 polymethacrylate monolithic capillary columns using laurylmethacrylate functional monomer and various cross-linking monomers differing in the polarity and size.

The column efficiency strongly depends on the size and polarity of the cross-linkers in the polymerization mixture. The efficiency of capillary monolithic columns for low-molecular compounds increases with the number of methylene units in non-polar (poly)methylene dimethacrylate cross-linkers, correlating with decreasing proportion of large through pores (> 50 nm) and increasing proportion of smaller mesopores (2 – 50 nm), as determined by inverse size-exclusion chromatography.

The efficiency for small molecules significantly improves when substituting non-polar (poly)methylene dimethacrylates with more polar (poly)oxyethylene dimethacrylate cross-linkers, showing important effects of cross-linker polarities on the chromatographic properties of polymethacrylate monolithic columns.

Here, the proportion of large through pores decreases with respect to the monoliths prepared with (poly)methylene dimethacrylate cross-linkers, however there is no clear correlation between the number of oxyethylene cross-linker units and the proportion of through pores or mesopores. This may be due to different solvation of monoliths in tetrahydrofuran used for size-exclusion determination of pore size distribution and in aqueous acetonitrile used as the mobile phase in reversed-phase separations.

It is well known that polyoxyethylene chains have surfactant properties, which affect their solvation properties. These results suggest that there may be different optimum cross-linker for the preparation of monolithic columns, depending on the type of sample to be separated.

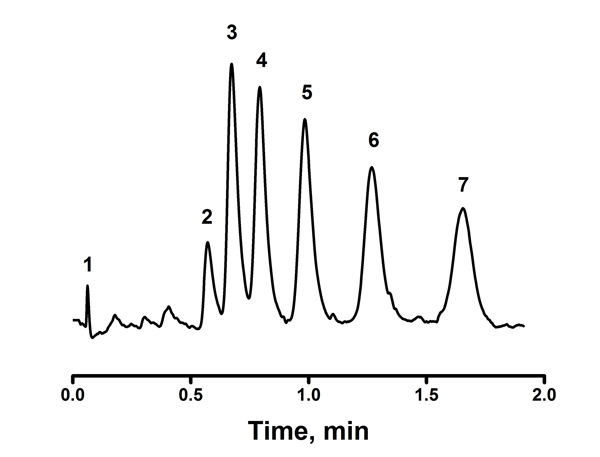

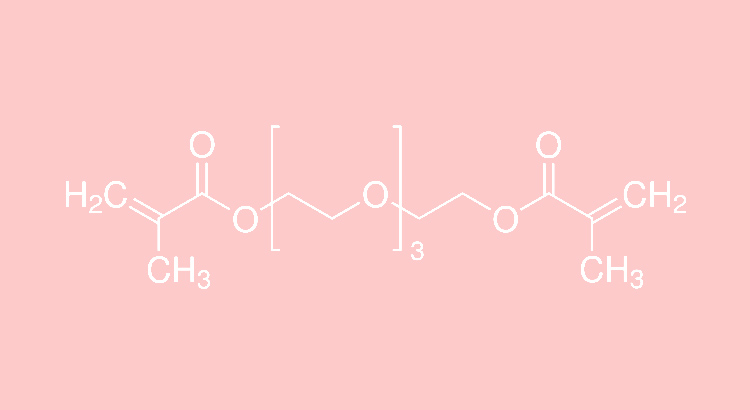

The columns prepared with tetraoxyethylene dimethacrylate cross-linker show high efficiencies of approximately 70 000 theoretical plates/m, high permeability, excellent reproducibility and long-term stability at elevated temperatures and can be used also in some size-exclusion applications. The figure shows the fast and efficient isocratic separation of low-molecular alkylbenzenes.

What it is?

So, what it is that makes these columns so efficient? It won’t be probably surface area as it is in the case of hypercrosslinked monoliths or polymers with styrenic and methacrylic monomers in the polymerization mixture.

More probably, there is an effect of gel porosity as described on monoliths polymerized for significantly shorter time. (But isn’t the hypercrosslinked layer at the surface of the polymer another type of “gel porosity”?)

Moreover, the swelling properties (gel porosity) and also column efficiency are definitely affected by the polarity of the polymerization mixture.

I believe that deeper study of the properties of very top layer of polymer monoliths which swells and is in direct contact with the mobile phase and their correlation with the polarity of the polymerization mixture might provide some clues or answers.

But that is for another study ….

What do you think? Leave me a comment, please!

One reply on “Crosslinking monomer: another way how to improve column efficiency”

Dear Dr Urban

My first question to you is that are you aware of any company that sells conventional monolithic columns methacrylate based, as all the companies that I have contacted the do not.

With best Wishes

Wael