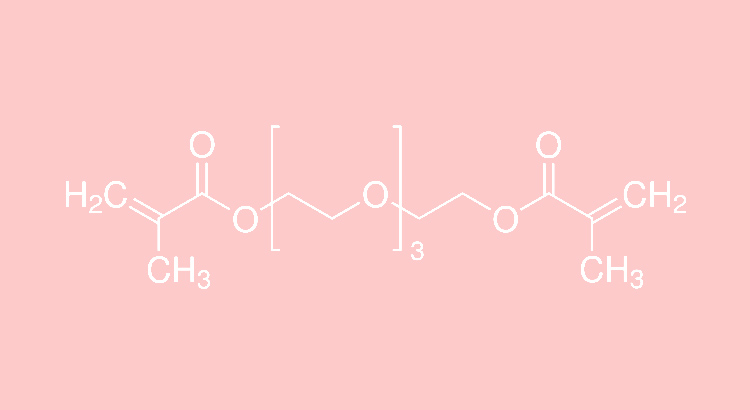

From my point of view, the preparation of polymer monolithic stationary phases suitable for the separation of small molecules is one of the hotter topics now in monolithic chromatography. There are several ways how to improve their separation power for small molecules. It is possible to increase their surface area either by hypercrosslinking modification or with the combination of non-polar and polar monomers. Another possibility is to prepare low-surface area (but efficient) materials by the termination of the polymerization reaction at the early stages or by application of crosslinking monomer with longer atom chain in between two methacrylate units.

We have extended the later approach and recently published the article describing the one-step preparation of highly efficient columns for the separation of small molecules.