The generally accepted mechanism of pore formation in organic polymer monolihts during a typical polymerization in the presence of a precipitant is following [1,2]:

The organic phase contains both monovinyl and divinyl monomers, initiator and porogenic solvent. The free-radical initiator decomposes at a particular temperature and the initiating radicals start the polymerization process in solution.

Nuclei formation

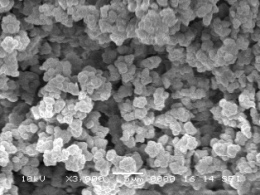

The polymers that are formed by solution polymerization precipitate after they became insoluble in the reaction medium as a result of both their cross-linking and the choice of porogen. In this process, the monomers are thermodynamically better solvating agents for the polymer than the porogen. Therefore, the precipitated insoluble gels like species (nuclei) are swollen with the monomers that are still present in the surrounding liquid. The polymerization then continues both in solution and within the swollen nuclei.

Branched or even cross-linked polymer molecules that can still be formed in the solution, are captured by the growing nuclei and further increase their size. The nuclei enlarged by the continuing polymerization, associate in clusters being held together by polymer chains that cross-link the neighbouring nuclei.

Later stage

In the later stages of the polymerization, the size of the clusters is large enough to allow contact with some of their neighbours thereby forming a scaffolding-like interconnected matrix within the polymerizing system [3].

Control of the kinetics of the overall process through the changes in reaction time, temperature, and overall composition allows the fine tuning of the macroporous structure and provides an understanding of the mechanism of large pore formation [3,4].

References

- J. Seidl, J. Malinsky, K. Dusek, W. Heitz, Adv. Polym. Sci., 5 (1967) 11.

- K.A. Kun, R. Kunin, J. Polym. Sci. A1, 6 (1968) 2689.

- F. Svec, J.M.J. Frechet, Chem. Mater, 7 (1995) 707.

- C. Viklund, F. Svec, J.M.J. Frechet, U. Irgum, Chem. Mater, 8 (1996) 744.